Tata Group hopes that the commercial production of semiconductors chips at the two plants – in Gujarat and Assam – whose foundation stones were laid on Wednesday, would start in 2026.

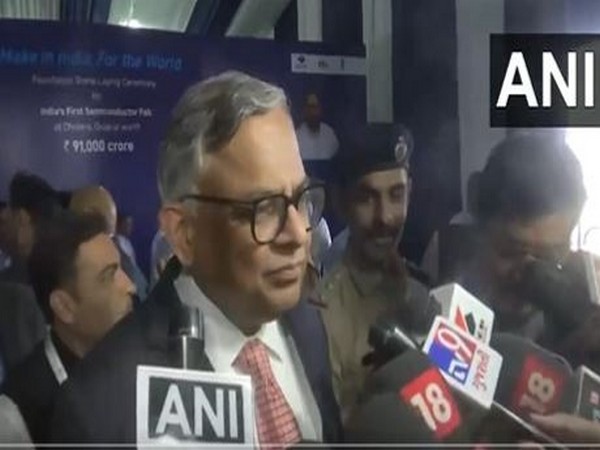

“We are accelerating the timeline. Typically, a fab takes four years, (but) our goal is to produce the chip in the calendar year 2026 – hopefully the later part of the year…We have a very aggressive timeline…(in) Assam (unit, it) will be done earlier, we may go commercial production in Assam even in late 2025 and early 2026,” said Tata Sons Chairman Natarajan Chandrasekaran, after the foundation stone laying ceremony, speaking to reporters.

The semiconductor manufacturing plants will also bring with it several job opportunities in Gujarat and Assam and will be a landmark in India’s Atmanirbhar efforts.

“We will create 50,000 jobs in this journey and this is just a beginning. Today our journey to build semiconductor has begun. For the first time India will have capabilities to solve the chips demand in India,” TATA Sons Chairman said.

In India’s endeavour to ramp up its semiconductor ecosystem, three new chip plants – two in Gujarat and one in Assam are being set up- in addition to the under construction chip plant at Sanand in Gujarat. Tata Group is setting up two of these three new plants.

As part of its Atmanirbhar and Make in India plan, the government launched production incentive (PLI) schemes in varied sectors, including electronics, to make Indian manufacturers globally competitive, attract investments, enhance exports, integrate India into the global supply chain and reduce dependency on imports.

The semiconductor industry in India is still in a nascent stage, with various local and multinational companies intending to tap its vast potential.

The Programme for Development of Semiconductors and Display Manufacturing Ecosystem in India was notified on December 21, 2021, with a total outlay of Rs. 76,000 crore.

Tata Electronics Private Limited (“TEPL”) will set up a semiconductor fab in partnership with Powerchip Semiconductor Manufacturing Corp (PSMC), Taiwan, in Dholera, Gujarat. Investment in this fab will be Rs 91,000 crore. PSMC has 6 semiconductor foundries in Taiwan. The capacity of the Dholera unit will be 50,000 wafer starts per month (WSPM).

Tata Semiconductor Assembly and Test Pvt Ltd (“TSAT”) will set up a semiconductor unit in Morigaon, Assam. With a capacity of producing 48 million chips per day, this facility is being built at a cost of Rs 27,000 crore. Segments that will be covered are automotive, electric vehicles, consumer electronics, telecom, and mobile phones.

These units will accelerate employment creation in downstream automotive, electronics manufacturing, telecom manufacturing, industrial manufacturing, and other semiconductor-consuming industries.

“Assam will see a lot of prosperity and a lot of jobs and it will change the face of that part of the world with this specific investment with regard to the capability…,” Chandrasekaran said.

Asked about expansion plans, Chandrasekaran said the focus now is on realising these two units.

“Once we have the production up and running, then we can talk about further expansion at this point in time. I think we should celebrate what we have set out to do fully recognizing that these are difficult projects and we are to keep our heads down and be realistic and ensure that we do a good job in producing the products that are appreciated and supported and meeting the demands of customers,” said the Tata Sons Chairman.

“It is definitely a pivotal moment. It is a very important day. Semiconductor is fundamentally required for anything digital. So, it is very important for India to become a semiconductor nation. I am very glad that Tata Group has been able to establish the first semiconductor fab also the first indigenous assembly unit in Assam,” he added.

During the main foundation laying ceremony, Chairman, TATA Sons, Natarajan Chandrasekaran said that semiconductors are a foundational industry for digital products just like steel is for physical infrastructure.

He noted that chip shortages during Covid realised the important of indigenous manufacturing to fill deficiency, for national security and galvanise indigenous innovation. (ANI)

For more details visit us: https://lokmarg.com/